ہمیں بلائیں

+86-19858305627

ہمیں ای میل کریں

sales@maple-machinery.com

کاسٹنگ کے ذریعہ تیار کردہ سٹینلیس سٹیل والو کی متعلقہ اشیاء مینوفیکچررز

ہماری فیکٹری ریت کاسٹنگ، کلوز ڈائی فورجنگ، اوپن ڈائی فورجنگ وغیرہ فراہم کرتی ہے۔ انتہائی ڈیزائن، معیاری خام مال، اعلیٰ کارکردگی اور مسابقتی قیمت وہی ہے جو ہر صارف چاہتا ہے، اور یہی وہ چیز ہے جو ہم آپ کو پیش کر سکتے ہیں۔ ہم اعلی معیار، مناسب قیمت اور کامل سروس لیتے ہیں۔

گرم مصنوعات

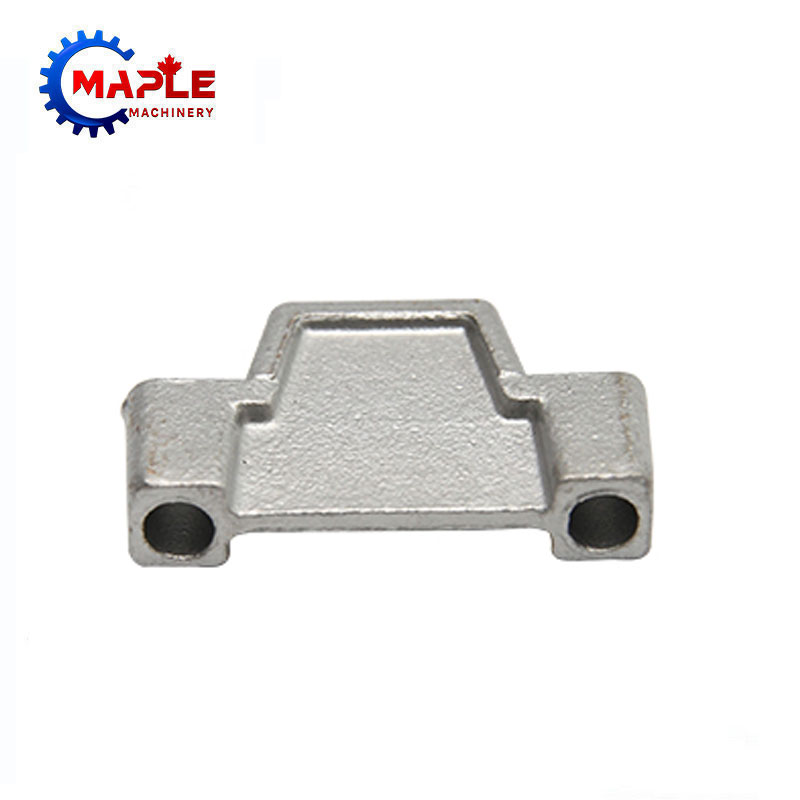

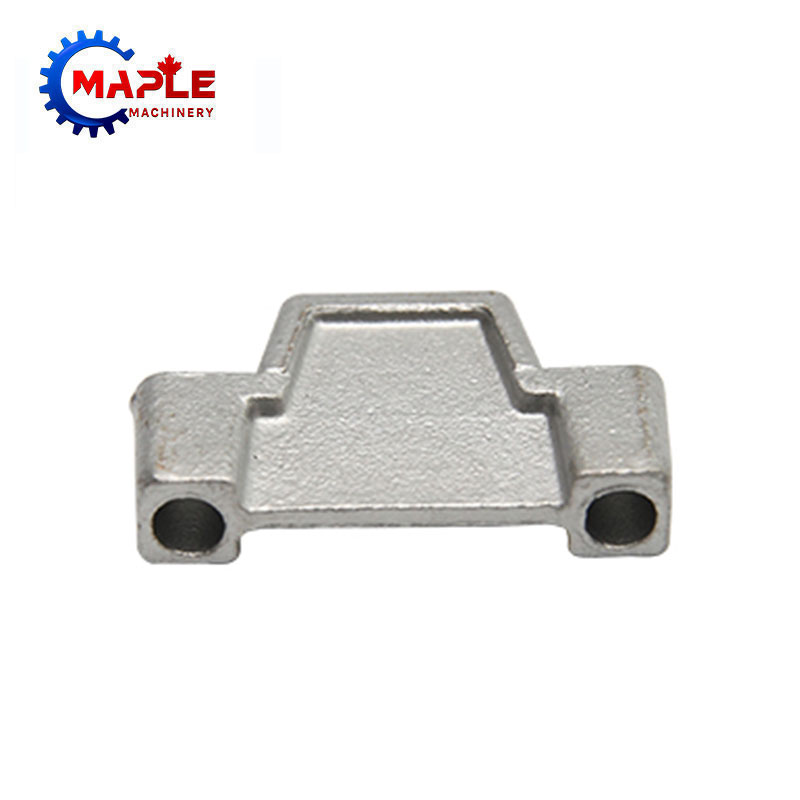

والو آئرن ریت کاسٹنگ پارٹس

میپل مشینری 15 سال سے زیادہ عرصے سے والو آئرن ریت کاسٹنگ پارٹس تیار کر رہی ہے اور ننگبو، چین میں مقیم ایک دھاتی صنعت کار ہے۔ مقصد دھاتوں اور دھاتی حصوں کی تیاری میں تکنیکی اور میٹالرجیکل پس منظر والی کمپنی بنانا تھا۔ ہمیں فخر ہے کہ ہم گزشتہ 15 سالوں سے اپنے عالمی صارفین کی مؤثر طریقے سے خدمت کر رہے ہیں۔ تب سے، ہم نے ریاستہائے متحدہ، کینیڈا اور شمالی امریکہ میں اپنے بہت سے مطمئن صارفین کی ضروریات کو پورا کرنے کے لیے اپنے تجربے اور تکنیکی مہارت کا فائدہ اٹھایا ہے۔ہیوی انڈسٹری گرے آئرن کاسٹنگ پارٹس

میپل مشینری ہیوی انڈسٹری گرے آئرن کاسٹنگ پارٹس بنانے والی کمپنی ہے، جو مختلف قسم کے کاسٹنگ کی تیاری میں مہارت رکھتی ہے۔ ہر رکن فرم کا اپنا مخصوص علم اور پیداواری ٹیکنالوجی ہے۔ تمام فاؤنڈریوں کی اپنی آزادانہ سرگرمیاں ہیں۔ کمپنی عالمی صارفین کے لیے اپنی مرضی کے مطابق آئرن ریت کاسٹنگ پارٹس بناتی ہے۔میرین گرے آئرن کاسٹنگ پارٹس

اپنے ترقیاتی اہداف کو حاصل کرنے کے لیے، میپل مشینری مسلسل ہمارے لوگوں، عمل اور مشینوں کی ترقی میں سرمایہ کاری کرتی ہے۔ سرمایہ کاری اور اختراع میرین گرے آئرن کاسٹنگ پرزوں کی دلکش دستکاری اور آج اور کل کی دنیا کی ضروریات کے درمیان ایک بہترین میچ کو یقینی بناتی ہے۔ مسلسل داخلی ترقی اور کمال کی ہماری جستجو کے نتیجے میں، ہم دنیا کے سرفہرست بانیوں میں سے ایک کے طور پر پہچانے جاتے ہیں۔ ہم فاؤنڈریوں اور مشین شاپس میں لاگو ٹیکنالوجی میں ایک واضح رہنما ہیں، اور ہمیں اس کامیابی پر بہت فخر ہے۔انڈسٹری آئرن ریت کاسٹنگ پارٹس

میپل مشینری انڈسٹری آئرن ریت کاسٹنگ پارٹس کا ایک کارخانہ دار ہے، جو مختلف قسم کے کاسٹنگ کی تیاری میں مہارت رکھتا ہے۔ ہر رکن فرم کا اپنا مخصوص علم اور پیداواری ٹیکنالوجی ہے۔ تمام فاؤنڈریوں کی اپنی آزادانہ سرگرمیاں ہیں۔ کمپنی عالمی صارفین کے لیے اپنی مرضی کے مطابق آئرن ریت کاسٹنگ پارٹس بناتی ہے۔ہیوی انڈسٹری اسٹیل ریت کاسٹنگ پارٹس

میپل مشینری اعلیٰ معیار کی ہیوی انڈسٹری اسٹیل ریت کاسٹنگ پارٹس میں مہارت رکھتی ہے اور اعلیٰ معیار والیوم پروڈکشن آرڈرز اور سنگل آئٹم پروڈکشن فراہم کرتی ہے۔ فاؤنڈری کا بنیادی مواد سٹیل کے مختلف درجات ہیں۔ اعلیٰ معیار کے کاسٹنگ کی تیاری کے سانچے کم سے کم مارجن کے ساتھ بعد میں پروسیسنگ کی اجازت دیتے ہیں۔ کاسٹ اسٹیل پیچیدہ جیومیٹری کے ساتھ مصنوعات فراہم کرتا ہے اور اس وجہ سے اکثر پیچیدہ ساخت کے ساتھ دھاتی مصنوعات تیار کرنے کا واحد طریقہ ہوتا ہے۔میرین سٹینلیس سٹیل فورجنگ پارٹس

میپل مشینری کا مقصد ہر لحاظ سے گاہک کی توقعات سے تجاوز کرنا ہے۔ ہماری ٹیم اس میں اہم کردار ادا کرتی ہے۔ میرین سٹینلیس سٹیل فورجنگ پارٹس تیار کرنے کے لیے صارفین کی توقعات پر پورا اتریں۔ ہم چاہتے ہیں کہ ہمارے صارفین پورے عمل کے دوران مطمئن رہیں اور ہماری خدمات اور مصنوعات سے پوری طرح مطمئن رہیں۔ بہر حال، مطمئن صارفین مستقبل کے آرڈرز کے مالک ہیں۔

انکوائری بھیجیں۔

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy