ہمیں بلائیں

+86-19858305627

ہمیں ای میل کریں

sales@maple-machinery.com

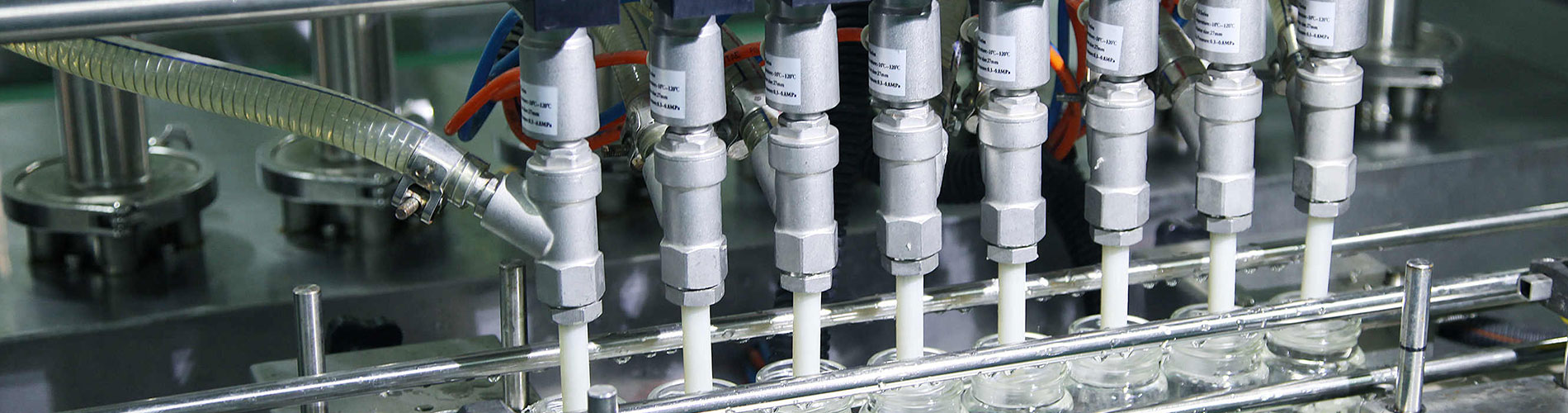

والوز کے لئے صحت سے متعلق کاسٹ حصوں مینوفیکچررز

ہماری فیکٹری ریت کاسٹنگ، کلوز ڈائی فورجنگ، اوپن ڈائی فورجنگ وغیرہ فراہم کرتی ہے۔ انتہائی ڈیزائن، معیاری خام مال، اعلیٰ کارکردگی اور مسابقتی قیمت وہی ہے جو ہر صارف چاہتا ہے، اور یہی وہ چیز ہے جو ہم آپ کو پیش کر سکتے ہیں۔ ہم اعلی معیار، مناسب قیمت اور کامل سروس لیتے ہیں۔

گرم مصنوعات

ہائیڈرولک سسٹم اسٹیل کاسٹنگ پارٹس

میپل مشینری ہائیڈرولک سسٹم اسٹیل کاسٹنگ پارٹس کی ایک بھرپور صنعت کار ہے۔ مصنوعات کو قابل اور وفادار ملازمین کے ذریعے بین الاقوامی سطح پر تیار، ڈیزائن، تیار اور فروخت کیا جاتا ہے۔ ہمارے نظام اور اجزاء کو عالمی سطح پر پراسیس انجینئرنگ سسٹمز میں استعمال کیا جانا چاہیے۔ ہم تمام صنعتوں کے لیے اعلیٰ معیار اور موثر ہائیڈرولک سسٹم اسٹیل کاسٹنگ پارٹس فراہم کرتے ہیں - گیئر پمپ سے لے کر الیکٹرانک کنٹرولڈ شافٹ، زرعی مشینری یا میٹل ڈائی کاسٹنگ مشینوں تک۔ ہمارے طویل مدتی صارفین ہماری مہارت اور تجربے پر بھروسہ کر سکتے ہیں۔ری سائیکلنگ انڈسٹری سٹینلیس سٹیل فورجنگ پارٹس

ایک زیادہ پائیدار دنیا کی تلاش میں، ری سائیکلنگ انڈسٹری سٹینلیس سٹیل فورجنگ پارٹس آرکیٹیکٹس، انجینئرز اور ٹھیکیداروں کے لیے ایک قابل قدر اتحادی ثابت ہوئے ہیں، جس کے متعدد فوائد نہ صرف پراجیکٹس بلکہ پورے معاشرے کے لیے ہیں۔ ری سائیکل شدہ صنعت کے سٹینلیس سٹیل فورجنگ پارٹس کے استعمال کے فوائد میں پروجیکٹ کی لاگت میں کمی اور جمالیات، وشوسنییتا اور پیشن گوئی میں اضافہ شامل ہے۔ پائیداری کے نقطہ نظر سے، سٹینلیس سٹیل کو جدید مادی ٹیکنالوجیز کے ساتھ ملانا نئی بلندیوں تک پہنچ سکتا ہے۔کان کنی کی صنعت آئرن ریت کاسٹنگ پارٹس

میپل مشینری تیز رفتار اور اعلیٰ معیار کے لوہے اور سٹیل کے پرزے اور کان کنی کی صنعت میں آئرن ریت کاسٹنگ پارٹس مہیا کرتی ہے۔ ہماری پیشہ ور فاؤنڈری، مولڈرز اور میٹالرجسٹ کی ٹیم کو صارفین کے ساتھ مسلسل تعاون میں کئی سالوں کا تجربہ ہے، اور وہ ہر بار قابل اعتماد نتائج کو یقینی بنانے کے لیے تکنیکی مواد اور عمل کی مہارت کا اطلاق کر سکتی ہے۔والو اسٹیل فورجنگ پارٹس

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.کان کنی کی صنعت سٹینلیس سٹیل کاسٹنگ پارٹس

MapleMachinery کان کنی کی صنعت سٹینلیس سٹیل کاسٹنگ حصوں میں تجربہ کار ہیں. مختلف قسم کے سٹینلیس سٹیل کاسٹ کرنے کی مضبوط صلاحیت کے ساتھ، ہم کان کنی کی صنعت کے لیے اپنی مرضی کے مطابق سٹینلیس سٹیل کاسٹنگ پارٹس اور اجزاء فراہم کرتے ہیں۔ ہم آپ کو اعلی معیار کی کان کنی کی صنعت کے سٹینلیس سٹیل کاسٹنگ پارٹس کی یقین دہانی کرا سکتے ہیں۔ ہم اس بات کو یقینی بنانے کے لیے اپنے صارفین کے ساتھ مل کر کام کرتے ہیں کہ سٹینلیس سٹیل کاسٹنگ پروڈکٹس/ اجزاء مطلوبہ خصوصیات کو انتہائی کم لاگت سے پیدا کر سکیں۔ ہم اپنے صارفین کے لیے بہترین سٹینلیس سٹیل کاسٹنگ سپلائی چین پارٹنر بننے کی کوشش کرتے ہیں۔آف ہائی وے انڈسٹری اسٹیل لوسٹ ویکس کاسٹنگ پارٹس

Maple machinery has a number of casting plants, with strong processing capacity Specializing in the production of carbon steel, alloy steel, stainless steel, high temperature alloy and other wax lost casting parts and machining parts. Maple's superior quality of Off Highway Industry Steel Lost Wax Casting Parts attracts equally excellent customers, enabling our products to serve various machinery industries. 产品内容 Off Highway Industry Steel Lost Wax Casting Parts Product Introduction Off Highway Industry Steel Lost Wax Casting Parts is a product that Maple machinery has been doing. Lost wax casting is now called investment casting. It is a precision casting process with little or no cutting. It is not only suitable for precision casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other precision casting methods. In order to meet the needs of different customers, we use two kinds of wax, namely yellow low temperature wax and green medium temperature wax. 2. Product Parameter (Specification) Item Off Highway Industry Steel Lost Wax Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel/Casting Iron Certification ISO 9001:2015 Weight 0.01-5000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Sand Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Off Highway Industry Maple machinery has been increasing its manufacturing capacity for Off Highway Industry Steel Lost Wax Casting Parts for many years. Provide high quality Off Highway Industry Steel Lost Wax Casting Parts for our machining operations to meet and satisfy customer needs. We are able to process different types of castings, including: pressure die casting and sand castings. We assist our customers to select the most appropriate casting type according to the required volume and complexity, providing the most cost effective solution. The railway sector provides a crucial network for transport and distribution. It needs cost-effective and long-lasting equipment that is dependable for the range of applications. The railways, from freight to passenger, need different castings for various applications. Maple Machinery carries extensive experience to create steel castings and iron castings in varying sizes, shapes, and materials that are precise, strong, and durable. We manufacture a wide range of castings and forgings for railway infrastructure and transportation equipment. 4.Supporting Service for Off Highway Industry parts As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Steel Lost Wax Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Off Highway Industry parts We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Steel Lost Wax Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Off Highway Industry We have manufactured a wide range of Off Highway Industry Steel Lost Wax Casting Parts. The following are typical products: Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar. 6. Why Sand Casting Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt. Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.

انکوائری بھیجیں۔

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy